Boat Trailer Springs

How often do you check your boat trailer springs? If your boat motor quits while out on water people people say you are "dead in the water." So, if you don't check your trailer springs you can be "dead on land" if they happen to break. This happened to us at PTF and is one of the of the things we have learned to do that prompted us to record and share this topic with others.

A few years ago, when we were getting our boat out of storage for spring fishing we noticed the trailer was not sitting even. Initially thought was we had a flat tire, however upon inspection we found the right rear leaf spring had broken during storage. The picture below is of the suspension showing a four leaf spring that is not broken.

Needless to say, plans for that day changed immediately. Instead of fishing that day, jack stands came out, right rear tires were removed to assess the broken spring. The largest leaf had broken in two where it met the next spring up. Checking the internet we found: www.stengelbros.com website and found everything we needed to replace the boat trailer springs. We replaced all springs so that the suspension stays evenly balanced with springs that are all the same age.

We are an Amazon Affiliate. If you purchase a product we recommend or another product while on Amazon, we may receive a small commission. Our staff recommends items that we have personally owned, used/tested, researched or we have fished with trusted anglers who recommend them. These products will not cost you any more than what is posted.

Double Axle Suspension Diagram

- 1 = Front and Rear Hangers

- 2 = Middle Hanger - Holding the Equalizer / Stabilizer

- 3 = Sidebars, Shackles

- 4 = Stabilizer, Equalizer

- 5 = Bolt and Lock Nut Location

Replacing Boat Trailer Springs

Since the axle, wheels and tires are basically "Floating" via the boat trailer spring suspension system - jacking up your trailer to work on requires extra thought. Place your jack so that it lifts a solid piece of the trailer frame. Be sure to use jack stands, or other solid material that will keep the trailer from falling while you are working with the suspension. Then begin removing the bolts, lock nuts, shackles, stabilizer bar (if you have a double axle) and the u-bolts and axle plates. Keep track of the order you remove these parts so that you can put them back on in reverse order and direction. Check for wear on any of these parts, and replace them if excessive wear is seen.

We are an Amazon Affiliate. If you purchase a product we recommend or another product while on Amazon, we may receive a small commission. Our staff recommends items that we have personally owned, used/tested, researched or we have fished with trusted anglers who recommend them. These products will not cost you any more than what is posted.

Boat Trailer Springs

There are two primary types of trailer leaf springs: Double EYE Leaf Springs (You will see an EYE on each end). Secondly, several varieties of Slipper/EYE leaf springs (You will see an eye on one end, and either a slipper-hook, a slipper-radius or slipper-flat on the other end.) Be sure to replace your current springs with the same type that you removed.

Stengel Brothers website is excellent and will walk you through all you need to repair or replace your boat trailer springs. We ordered four springs, that were Double Eye, each were four leaf. We did not need to replace any other parts because there was little to no wear on them. We did have to order new U-Bolts as explained below. Within a week the springs arrived with the U-Bolts. Replacing all four springs was an afternoon job.

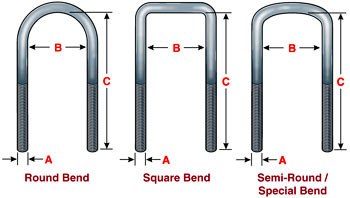

How to Measure Springs

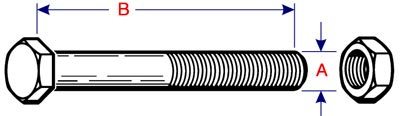

Our Lund Boat with Heritage Trailer had four springs that each were three leaf. They were rated at 1250 lbs each. Since our boat, motor and trailer fully loaded was right at 5000 pounds we determined that we would replace all springs with stronger leaf springs, and moved up to springs that were four leaf, and rated 1500 lb each. This also meant that we needed to order longer U-Bolts for our axle mount. Next we measured the old leaf springs. Stengel Brothers Trailer Springs walks you through how to do this and offers a phone number if you have questions. They have springs of virtually every size, rated weight capacity, and choices of 3, 4 or more leaves. In order to double check measurements we traced the outline of one spring on a large piece of cardboard, then used a tape measure to measure the dimensions - we wrote down all the dimensions shown in the drawing above.

Trailer Spring Shackle

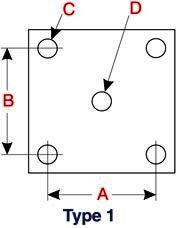

Trailer spring shackles (also called SideBars) are made of heavy gauge steel. They are very rugged but over time may begin to show wear. These are part of the suspension assembly that allows the axle to float. Upon removing inspect for wear. If you need to replace these sidebars then make the measurements seen in the drawing, being careful to pick the diameter of the hole that will match the size of your bolt.

Trailer Spring Hangers

and Stabilizer

Inspect for worn, broken or loose fitting parts. Wear or rust would be the most likely cause of needing to make a change. Hangers are used to "Hang" your boat trailer springs from the frame of your trailer. A double axle trailer will most likely have three hangers - one on each side of the trailer - a front, middle and rear hanger. These hold the front eye of the front trailer spring, the stabilizer bar in the middle, and the rear eye of the rear spring.

Hanging in the middle on each side of the trailer is a stabilizer. The other ends of the front and rear spring are connected to the stabilizer bar by the shackles (sidebars) mentioned above. Note how the stabilizer bar in the picture above is bolted to the hanger in the middle that is welded to the frame of the trailer and shows the sidebars or shackles. Note the position of the shackles and be sure to replace them in the same position.

Trailer Axle U-Bolts and Plates

The Axle U-Bolts, lock nuts and plates secure the axle to the middle of each trailer leaf spring. So are you getting the picture now? Each trailer spring is connected to the frame of the trailer via hangers, shackles/sidebars, and/or an equalizer if you have a tandem axle trailer, then the axles are connected to each trailer spring.

U Bolts and U Bolt Plate shown below.

Boat Trailer Lock Nuts/Bolts

In most cases you will find heavy duty 9/16 inch lag bolts that are long enough to pass through the spring eyes, bushings, and leave enough room for the nut to be secured. Only the portion of the bolt that sticks through for the nut is actually threaded so the the springs, stabilizer bar, and suspension flex around the bushings and won't wear because the bolt is actually smooth where it passes through the bushing. (That is what the Lag Means) Lock nuts are used to ensure that the nuts do not come loose. Lock nuts have a built in plastic/nylon material on about half the threads so that when you tighten the nut that nylon material begins to grab the bolt. You will know it is time to use your wrench when you can no longer tighten the nut with your fingers.

Now you should be ready to tackle inspection and replacement of your boat trailer springs if and when needed. We strongly recommend going to a local trailer supply company, take your part so you can match exactly what you need to replace.

Other Boat Trailer Parts

- Trailer Tires

- Trailer Bearings and Bearing Grease

- Trailer Lights and Boat Wiring

- Trailer Rollers

- Trailer Hitch and Ball Mounts

- Trailer Jacks

Take care of your boat trailer springs and they will take care of you!